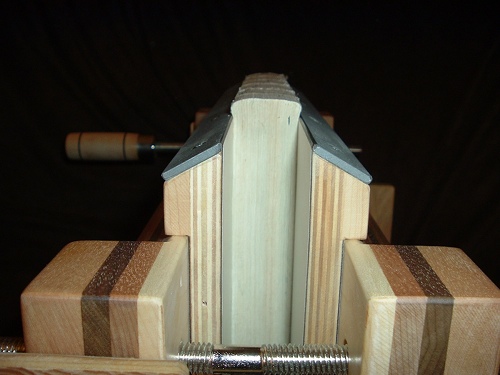

This is a pair of steel-edged backing irons for bookbinding, used to “back” or form the spine of text block before casing it in during the book binding process. The text block is placed between the 2 boards in a press with a small portion exposed and then shaped with a backing hammer.

The backing irons are made from 1/2″ Baltic birch plywood with a hardwood lip and are 6” wide and 14-1/2” long. The steel is beveled to 30 degrees (unlike most other irons where they just use the steel as they get it, rounded on the edges) so you get a nice crisp corner, and it is attached with glue and screws. Will take years of punishment without fail,something wood backing boards can’t do. These backing irons are made to fit the finishing press sold here. These are not wedged shaped but there is enough pressure at the irons to press the text block tight to back the spine.

The inner part that touches the text block is covered with white plastic laminate, the same that is used for kitchen countertops. This makes the boards waterproof and easy to clean. It also makes it easy to remove glue from them. The steel has a very small radius to keep it from cutting into the paper when backing. All exposed wood is sealed with danish oil finish and waxed to a smooth natural finish.

This design is an improvement over the traditional design because of the lip. As the book is placed in the press, there is no need to worry about the whole thing falling through the press as it will stop at the lip (see above). Also, the steel is covered on the text block side with the laminate so the only paper that will touch the steel will be the small radius part. This alleviates any concern there might be for any rust or steel particles rubbing off on the text block.

The pictures here demonstrate a set of backing irons in a finishing press (sold separately).

Purchase these Backing Irons – $115

Purchase and take delivery of these backing irons by following the steps on the purchase page. Customized backing irons for bookbinding are available too. Send your special requirements through the contact page and I will get back to you.

Go here to see a monster set of backing irons I made for a conservationist.